RANDOM ORBITAL:

The backing plate follows an orbit (the amplitude of which depends on the distance between the rotation axis of the drive shaft and the central axis of the backing plate) and is free to rotate about its own central axis. The backing plate is free to rotate at varying velocities and directions by the effect of the centrifugal force of the offset movement and by the effect of friction. Should the friction forces be such as to prevent rotation of the disc while the tool is still operating, the random orbital movement would simply become an orbital movement. The number of disc rotations is variable and independent of the number of orbits performed. The random orbital movement is at present the best compromise in terms of effectiveness and surface treatment quality.

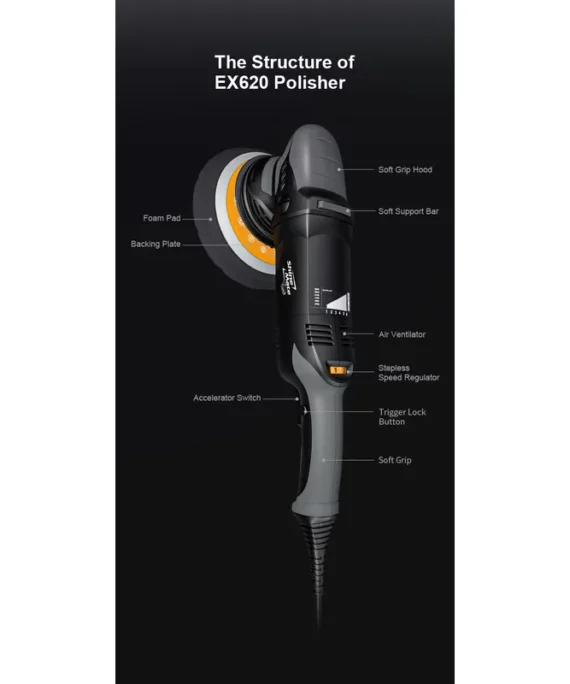

IMPROVED ERGONOMICS:

The rubberized front grip of the MarkIII offers exceptional comfort for the operator while providing a non-slip surface for control. The improved rear handle also integrates rubberized surfaces for an improved feel. Two strategically placed, non-marking, tool rests provide stability when the tool is not in use as well as additional protection against unintended impact. The continued refinement of the BigFoot random orbital platform in MarkIII reinforces its best-in-class reputation, making the best even better.

ELECTRONIC SPEED CONTROL DIAL:

The new electronic speed control dial allows for easy adjustment of the top speed of the polisher without requiring the operator to move his hands. The larger dial is easily adjusted with a move of the thumb. High visibility numbers and more positive feedback from the movement of the dial make speed changes feel more deliberate, allowing operators to select the ideal speed for the task without any interruption to the polishing process.

9 METERS ELECTRICAL CORD:

The new Heavy Duty extra long 9mt cord is gauged to deliver maximum power to the polisher for safe, efficient operation. The longer cord save you time, steps and hassles since the user doesn’t have to use additional extension cords when polishing around a car.

PROGRESSIVE TRIGGER:

Adding an additional layer of control is the new progressive trigger. Acting as a throttle to control speeds within the dial range, the progressive trigger allows the operator to make subtle adjustments for precise control without interrupting the process or the need to reposition the grip to access the speed dial.

DESIGN:

Attention to detail is something more than just attractive design. Every detail, such as the rubber support positioned on the body of the machine to keep it stable during the non-working stages, is the result of meticulous research aimed at achieving maximum operator comfort.